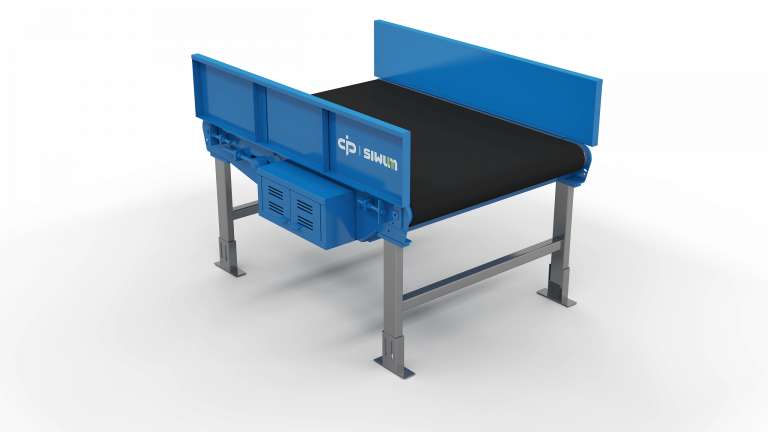

SIWUN Logistics Telescopic Belt Conveyor

Telescopic Belt Conveyor is designed to extend and retract, allowing for flexible adjustment of the conveyor length to adapt to different working spaces and material handling requirements.

- Efficient Loading and Unloading: Telescopic belt conveyorsignificantly improves the efficiency of loading and unloading goods in logistics, warehousing, and transportation.

- Smooth Operation: Equipped with a stable drive system, this sorting conveyorensures smooth and continuous movement of goods on the conveyor belt, reducing the risk of damage to items during transfer.

- Flexible applications:Telescoping conveyors can handle goods of different weights and sizes, making it suitable for various industries such as manufacturing, logistics, and e-commerce.