Today’s warehouses handle exponentially more SKUs, process orders across multiple channels, and must deliver with unprecedented speed and accuracy. This complexity has made logistics software not just beneficial, but essential for survival in the competitive marketplace.

Logistics software serves as the digital brain of modern warehouse operations, orchestrating everything from inventory management to last-mile delivery. The integration of various software solutions creates a unified ecosystem that provides visibility, control, and optimization across the entire supply chain.

Copyright image from https://www.freepik.com/free-vector/isometric-export-import-isolated-composition-with-world-map-background-warehouse-building-with-multiple-cargo-vehicles-vector-illustration_41916976.htm

Table of Contents

ToggleKey Software Categories in Logistics

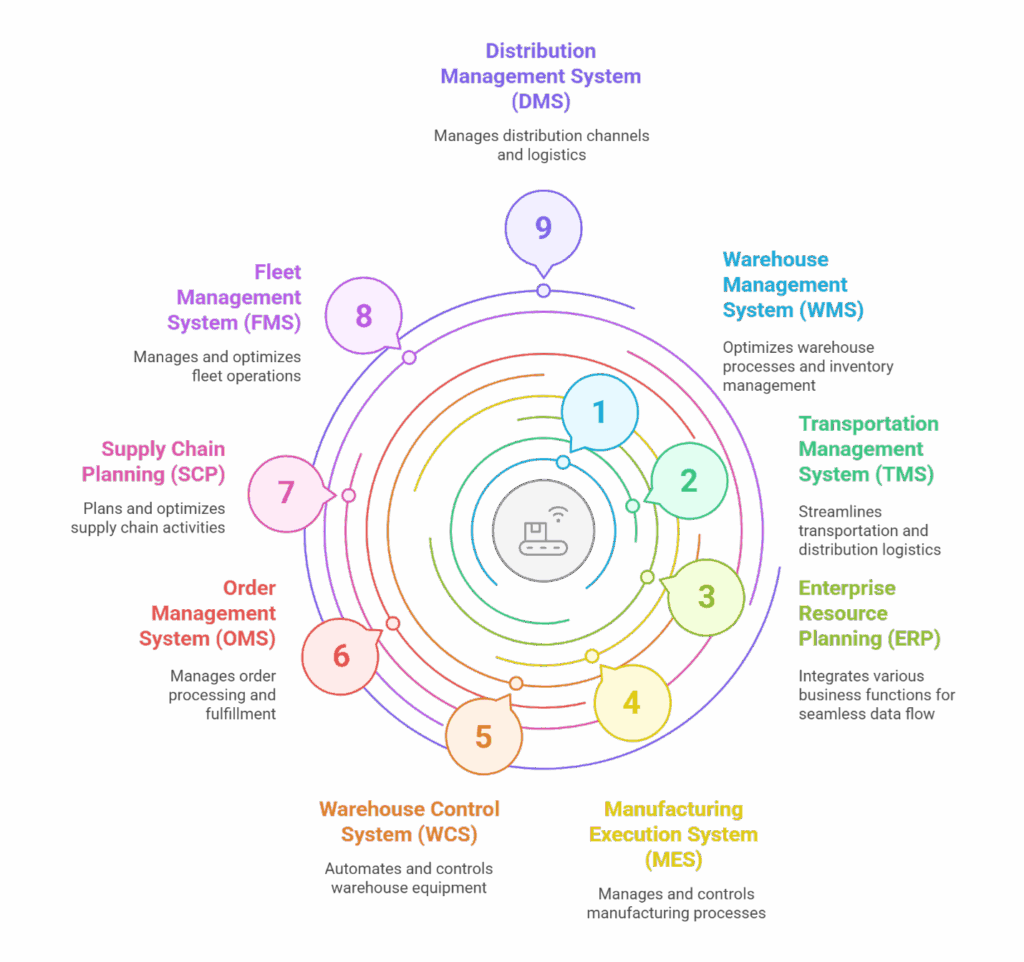

The logistics software ecosystem encompasses several critical categories, each designed to address specific operational challenges.

- Warehouse Management System (WMS)

These systems provide real-time inventory tracking, optimize picking & packing processes, and manage warehouse layout for maximum efficiency. Modern WMS solutions also offer advanced features including cycle counting automation, slotting optimization, and labor management capabilities that dramatically improve warehouse productivity.

- Transportation Management System (TMS)

These systems offer sophisticated route planning algorithms, comprehensive carrier management, and detailed freight auditing capabilities. They can also reduce transportation costs through optimized routing and carrier selection.

- Enterprise Resource Planning (ERP) Systems

ERP systems offer unprecedented supply chain visibility and enable data-driven decision making. When properly integrated with WMS and TMS, ERP systems can create a seamless flow of information that eliminates silos and reduces operational friction.

Additional specialized systems include Manufacturing Execution Systems (MES), Warehouse Control Systems (WCS), Order Management Systems (OMS), Supply Chain Planning (SCP), Fleet Management Systems (FMS), and Distribution Management Systems (DMS), each addressing specific operational requirements within the broader logistics ecosystem.

WMS: Enhancing Warehouse Efficiency

Warehouse management systems have evolved far beyond simple inventory tracking to become comprehensive operational platforms. Modern WMS solutions deliver inventory accuracy rates exceeding 99.5% through real-time tracking and automated data capture technologies. Task automation capabilities include intelligent work prioritization, automated replenishment triggers, and dynamic slotting recommendations that optimize warehouse layout based on product velocity and picking patterns.[1]

Labor optimization features within WMS platforms can improve productivity by up to 30%, with early adopters reporting planning time reductions of 30% and operational cost savings between 20% and 25%.[1] These systems provide managers with detailed analytics on individual and team performance, enabling targeted training and process improvements.

Key operational enhancements include:

- Mobile-enabled picking and receiving processes that reduce errors and increase speed

- Advanced yard management capabilities that optimize dock scheduling and trailer utilization

- Comprehensive returns handling workflows that streamline reverse logistics operations

- Integration with automated material handling equipment for seamless operations

The mobile capability aspect deserves particular attention, as mobile WMS applications enable real-time data capture at the point of activity, eliminating paper-based processes and reducing the time lag between physical actions and system updates.

TMS: Streamlining Transportation and Distribution

Transportation management systems address the increasingly complex challenge of moving goods efficiently and cost-effectively. Modern TMS platforms offer real-time shipment tracking that provides complete visibility from pickup to delivery, enabling proactive exception management and improved customer communication. Optimized routing capabilities utilize sophisticated algorithms that consider factors including traffic patterns, driver hours of service, fuel costs, and delivery time windows to create the most efficient routes possible.

Critical TMS functionalities encompass:

- Load building optimization that maximizes trailer utilization and reduces empty miles

- Electronic Proof of Delivery (ePOD) systems that accelerate billing cycles and improve cash flow

- Comprehensive freight auditing capabilities that identify billing errors and ensure contract compliance

- Advanced analytics platforms that provide insights into carrier performance, shipping costs, and service levels

- Multi-modal planning capabilities that optimize the selection between different transportation modes

The integration of artificial intelligence and machine learning in modern TMS solutions enables predictive analytics that can forecast potential delays, recommend alternative routing options, and optimize inventory positioning based on transportation constraints.

ERP Integration: Creating a Unified Logistics Ecosystem

The true power of logistics software emerges when individual systems work together as a unified ecosystem. ERP integration serves as the foundation for this connectivity, enabling seamless data flow between warehouse management, transportation, and broader business operations.

Integration Benefits and Considerations

Effective ERP-TMS-WMS integration eliminates data silos that traditionally plagued logistics operations, creating a single source of truth for inventory levels, order status, and operational performance. This integration enables cross-functional visibility that allows different departments to access real-time information and make informed decisions quickly.

According to Grand View Research, the global warehouse management system market is projected to grow from $2.8 billion in 2021 to $6.1 billion by 2026, representing a compound annual growth rate of 16.7%.[2] This growth reflects the increasing recognition of integrated logistics software as a competitive advantage.

The benefits of integrated systems include accelerated decision-making processes, improved customer service through better visibility, reduced operational costs through elimination of redundant data entry, and enhanced scalability as business requirements evolve.

Copyright image from https://www.freepik.com/free-photo/standard-quality-control-concept-m_36027715.htm

Choosing the Right Software Stack

The selection of appropriate logistics software depends heavily on business size, operational complexity, and growth projections. Small to medium-sized businesses may benefit from cloud-based solutions that offer lower upfront costs and faster implementation timelines, while larger enterprises often require more robust, customizable platforms that can handle complex operational requirements.

Key selection criteria include:

- Integration capabilities with existing systems and future technology investments

- Scalability to accommodate business growth and seasonal fluctuations

- Vendor support quality, including implementation services and ongoing technical assistance

- Total cost of ownership, considering licensing, implementation, training, and maintenance costs

- Industry-specific functionality that addresses unique operational requirements

The evaluation process should include detailed requirement gathering, vendor demonstrations with real data scenarios, reference checks with similar organizations, and comprehensive total cost of ownership analysis.

For organizations seeking comprehensive logistics management solutions, Siwun provides integrated capabilities across the entire logistics ecosystem through its advanced equipment control systems. By embedding functions such as warehouse management, transportation optimization, and enterprise system integration, Siwun enables seamless logistics operations and supports business growth.

Conclusion

The strategic importance of a connected logistics software ecosystem cannot be overstated in today’s competitive marketplace. Organizations that successfully integrate WMS, TMS, and ERP systems create significant competitive advantages through improved efficiency, reduced costs, and enhanced customer service capabilities.

As logistics operations continue to evolve, the software systems that support them must be flexible, scalable, and capable of adapting to new challenges and opportunities. The future of logistics belongs to organizations that embrace integrated software ecosystems as the foundation for operational excellence. By investing in the right combination of logistics software solutions, companies can transform their operations from cost centers into competitive advantages that drive business success.

References

[1] https://www.researchgate.net/publication/388843015_Warehouse_Management_System_with_IoT_A_Comprehensive_Guide

[2] https://en.wikipedia.org/wiki/Warehouse_management_system