The global logistics industry is at a major turning point. A perfect storm of surging e-commerce growth, persistent labor shortages, and the unsustainable costs of manual handling has created a new reality for fulfillment centers and delivery operations. The traditional model of relying on human labor is no longer just inefficient; it’s becoming financially and operationally unmanageable. In 2024, the U.S. domestic parcel market handled up to 23.8 billion shipments, a volume 1.5 times higher than pre-pandemic levels, while a structural labor shortage has left 70% of U.S. employers struggling to find staff.[1]

In this challenging environment, automation is not just an option for a competitive edge but a fundamental requirement for survival. It offers a path to reducing labor costs, boosting efficiency, and minimizing the errors and damage associated with manual handling. At the heart of this automated revolution is a critical piece of technology: the parcel singulator. This guide explores what a singulator is, how it works, and why it has become an indispensable tool in modern logistics.

Table of Contents

ToggleWhat Is a Singulator?

An automatic parcel singulator is a specialized conveyor system that brings order to the chaos of bulk parcel flows. Its primary function is to transform a disorganized, multi-lane stream of packages into a perfectly organized, single-file line of items.

The key objective is to ensure that every parcel is individually separated, correctly oriented, and uniformly spaced before it reaches downstream automated processes. These subsequent steps include crucial data-capture systems like barcode scanners and in-motion weigh scales, as well as the high-speed sorters that physically route packages. By solving common issues like “side-by-side” packages that can cause jams or read errors, the singulator acts as the essential pacemaker for the entire automated sorting hub, ensuring the multi-million-dollar sorting systems can run at peak efficiency.

How Does a Singulator Work?

A modern singulator masterfully combines electromechanical engineering and artificial intelligence to orchestrate the flow of parcels. The transformation from bulk flow to a single file happens across four distinct stages.

1. Input & Accumulation

The process begins when a dense, disorganized flow of parcels is loaded onto an accumulation conveyor. This section acts as a buffer zone, absorbing the initial surge and using a series of controlled zones to “meter” the parcels, creating small initial gaps in the flow. Advanced systems use Zero-Pressure Accumulation (ZPA), where sensors ensure parcels never touch, which is essential for fragile or irregularly shaped items.

2. Scanning & Perception

Parcels then move under the “eyes and brain” of the system: an advanced vision system. High-resolution 3D cameras or laser profilers generate a detailed 3D map of every item. This data is fed to a computer running AI software, which analyzes the shapes, sizes, and relative positions of all parcels to identify individual items and detect problematic situations like stacked packages. Based on this analysis, it generates precise commands for the mechanical systems.

3. Singulation & Alignment

This is where the vision system’s commands become physical action. The singulator uses a series of independently controlled modular belts that can speed up or slow down to create precise gaps and rotate items. Many systems also incorporate sections of skewed rollers that gently push parcels to one side of the conveyor, forcing them into a single-file line and resolving side-by-side issues.

4. Output & Gapping

The final output is a perfectly organized, single-file stream of parcels. Crucially, the items are not just in a line; they are “gapped” with a consistent and predefined space between each one. This gap is a technical necessity, giving downstream sorting mechanisms the time and space needed to actuate, sort the parcel, and reset for the next one without causing collisions or jams.

Key Features and Advantages

High-performance singulators are defined by a set of key hallmarks that distinguish them in the competitive automation market.

1. High Throughput

A singulator’s most basic performance metric is its throughput, measured in parcels per hour (pph). This directly determines a facility’s overall capacity. Top-tier systems like the MHS ARB Singulator can handle up to 12,000 pph, while the Körber Visicon boasts rates of up to 18,000 pph.

2. Accuracy

Speed is useless without precision. Leading systems achieve near-perfect accuracy rates of over 99%, with some models like the Fives SOLI-Modular™ claiming 99.99% accuracy—equivalent to one error per 10,000 items. This reliability is critical to prevent downstream chaos and line stoppages.

3. Energy Efficiency

With rising energy costs, efficiency is a key consideration. Modern singulators incorporate features like variable-speed drives that match power to parcel volume, low-power “sleep modes” for idle periods, and even the ability to recuperate kinetic energy during braking.

4. Modular Design

A modular design, where the system is built from smaller, independent units, offers incredible flexibility. It allows companies to scale their systems by adding modules as volume grows, fit automation into tight or existing spaces, and simplify maintenance and upgrades.

5. Smart Identification

The modern parcel stream is incredibly diverse, from rigid boxes to flimsy polybags. The AI-driven vision systems in advanced singulators can recognize and adapt their handling strategy for virtually any package type, ensuring high performance regardless of the item mix.

Industry Applications

Singulators are being deployed across the logistics landscape to solve critical bottlenecks in diverse environments.

1. Large Sorting Hubs

Global carriers like DHL, UPS, and FedEx operate massive “mega-hubs” where singulators are a non-negotiable component. They are the essential feeders for enormous sorting systems that process tens of thousands of parcels per hour, ensuring these facilities can operate at peak capacity.

2. Compact Terminals

For years, high costs and large footprints made automation inaccessible for smaller regional hubs or 3PLs. However, the advent of compact, modular singulators is democratizing this technology. The Körber Visicon Compact, for instance, can process up to 7,000 pph in a footprint of less than seven square meters, making advanced automation feasible for smaller operators.

3. Robotic Integration

There is a deeply symbiotic relationship between singulators and robotics. A robotic picking arm needs a predictable and well-presented stream of items to work efficiently. In one model, a singulator prepares an orderly flow for a robot to perform a task. In a more advanced model, the robot becomes the singulator, using 3D vision to pick items directly from a chaotic pile and create a perfect single-file stream on its own.

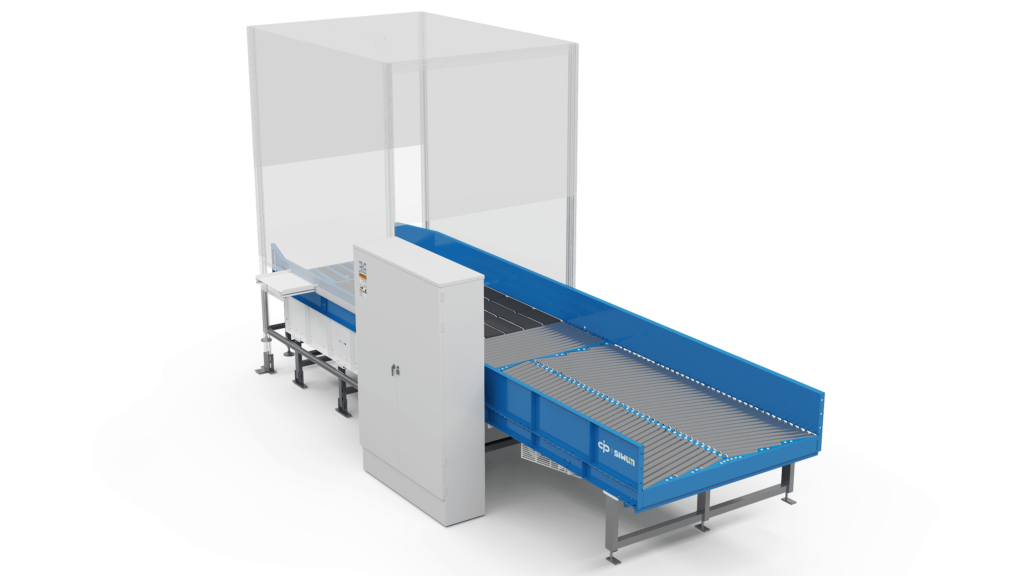

Siwun's Automatic Parcel Singulator

The Siwun Automatic Parcel Singulator serves as an excellent case study of a modern system that blends throughput, accuracy, and intelligent control. Its features are designed to meet the diverse needs of today’s logistics operations.

Engineered for robust performance, Siwun automatic parcel singulator comes in models capable of processing up to ≥6,500 parcels per hour, placing it in the mid-to-high range of the market. It achieves a high separation success rate of ≥99% for standard parcels and demonstrates its versatility by handling a vast range of items, from small flats (120x120x1mm) to large cartons (1000x700x700mm). Key technological features include:

- Dynamic Spacing Control: An intelligent control system that dynamically adjusts the gapping between parcels in real-time to perfectly match the speed and needs of the downstream sorter, optimizing throughput.

- Rapid Bulk Loading: The system is designed to accept parcels unloaded in bulk, significantly increasing unloading speed and reducing the physical strain on dock workers.

- Real-Time Process Optimization: A continuous feedback loop from sensors allows the system to make ongoing adjustments, ensuring consistent and reliable performance.

Concluison

In the face of unprecedented parcel volumes and persistent labor shortages, the singulator has evolved from a specialized piece of machinery into a cornerstone of modern logistics automation. It is a strategic enabler of efficiency, allowing facilities to process more packages with fewer errors, less labor, and in a smaller footprint. By transforming chaotic bulk flow into a perfectly prepared stream for high-speed sorting and robotics, the parcel singulator provides the reliability and control necessary for logistics companies to survive and thrive in the demanding era of e-commerce.

Reference

[1] https://www.pitneybowes.com/us/shipping-index.html