Agv Robot Warehouse

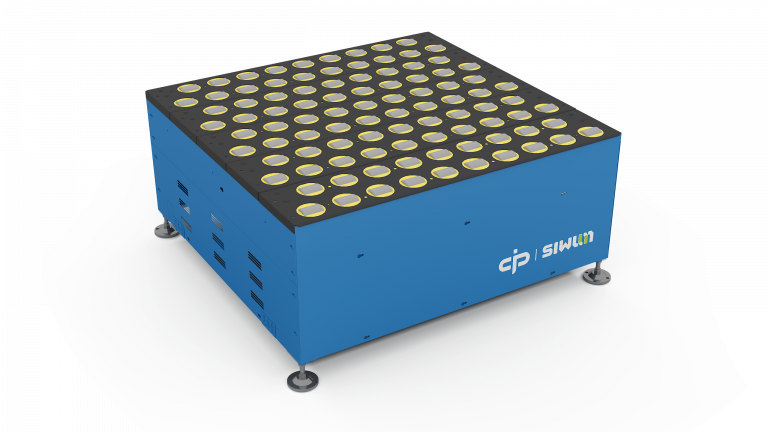

You are most welcome to come to China, to our city and our factory! We glance ahead on your pay a visit to and developing trustworthy and long-term standing relationship. While in the past few years, our organization absorbed and digested advanced technologies, defining our professional approach. We are looking forward to cooperating with you and providing our best services for you, as well as our agv robot warehouse, Cross-belt Sorter,Logistics Software Systems. Nowadays with the social and economic pace, we’ve got decided to capitalize on global opportunities. We expect to provide agv robot warehouse and services to more users in global markets including South Asia, North Africa, Mexico, Western Europe, etc. As a reliable and professional company, Siwun Logistics partners with skilled tech teams and offers the best solutions as well as agv robot warehouse to global customers. We strive to improve our service and provide the best quality products, dedication to high-quality is our life, trust paves our way to success. To ensure your satisfaction, we contine to enhance production quality and effeciency, tailoring production according to your needs is fine, each product has been professionally certified to meet industry standards.