For system integrators tasked with designing the backbone of a modern distribution center, the choice of sorting technology carries decades-long implications. Among the top contenders, the cross-belt sorter stands out for its versatility and reliability. A deep understanding of its working principle is essential not just for selection, but for designing the optimal material flow, induction systems, and controls around it.

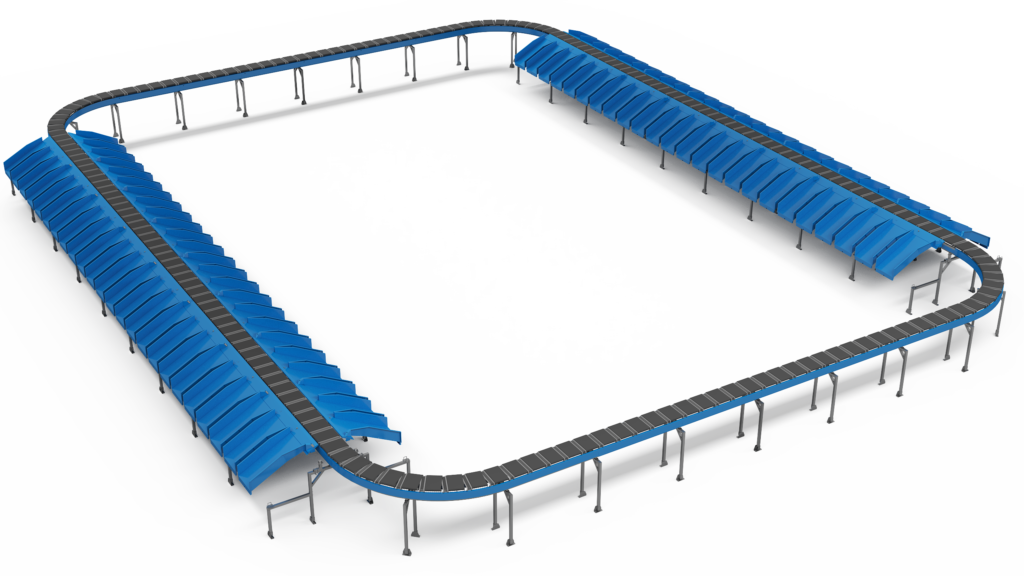

At its heart, the conveyor sorter system is an elegant exercise in modular automation. The system comprises a closed-loop track upon which a series of individual, self-powered carts circulate. Each cart is equipped with its own small belt sorter, mounted perpendicular to the direction of travel—this is the “cross belt.” The process begins at the induction stations, where a single parcel is dynamically placed onto a vacant cart. As the cart journeys through the system, it passes a scanning tunnel where omnidirectional cameras capture the parcel’s barcode or shipping label. This data is instantly relayed to the Warehouse Control System (WCS), which calculates the precise destination and communicates it to the cart’s onboard controller.

The magic happens at the discharge point. Instead of tilting or pushing, the cart’s cross belt simply activates, carrying the parcel laterally off the main path and depositing it gently and accurately onto a designated take-away chute or conveyor leading to a loading dock, gaylord, or pallet zone. Because the item is carried off rather than pushed or dropped, the system is exceptionally gentle, making it ideal for a vast range of products, from fragile electronics and irregularly shaped packages to heavy items up to 50 kg.

For integrators, this translates to unparalleled design flexibility. The independent nature of each cart allows for simultaneous sorting to hundreds of destinations, complex sort patterns, and bi-directional sorting. The system’s ability to handle a massive SKU mix future-proofs a facility against changing inventory profiles. SIWUN provides robust automatic sorting machines and solutions built on this proven and reliable principle, offering system integrators a powerful, flexible, and high-performance tool for building the distribution centers of today and tomorrow.