In the high-stakes environment of modern aviation, the passenger experience is often defined by a single, silent variable: the baggage.

For industry insiders, we know the reality behind the glossy terminal facades. During peak operational hours, baggage processing stops being a background utility and becomes the absolute backbone of passenger flow. When that backbone fractures—due to a mechanical bottleneck or a software synchronization error—the ripple effect is immediate. Flight delays pile up, connection windows are missed, and operational costs skyrocket.

At Siwun, we view baggage handling not just as moving luggage from Point A to Point B, but as a complex logistical equation that requires precision engineering. With the global airport automation market projected to grow from $10.8 billion in 2022 to $19.6 billion by 2032, the industry is signaling a clear shift: the era of manual reliance is ending. The future belongs to intelligent, automated resilience.

The High-Pressure Challenge: Why Reliability Costs Billions

The cost of failure in baggage handling is quantifiable and staggering. Despite the industry’s success in reducing mishandling rates by half since the 2007 peak, the sector still spends over $2 billion annually on claims and the logistical nightmare of reuniting passengers with lost bags.

But the financial loss is only half the story. A delayed bag is often the tipping point that negates an otherwise positive flight experience. In our experience working with logistics hubs, we have seen that labor shortages are no longer a temporary issue—they are the new normal. Automation is the only viable lever to lower airport operating costs while solving the chronic workforce gap. The goal is simple yet difficult to achieve: consistent performance under extreme pressure.

Deconstructing the Smart Baggage Chain

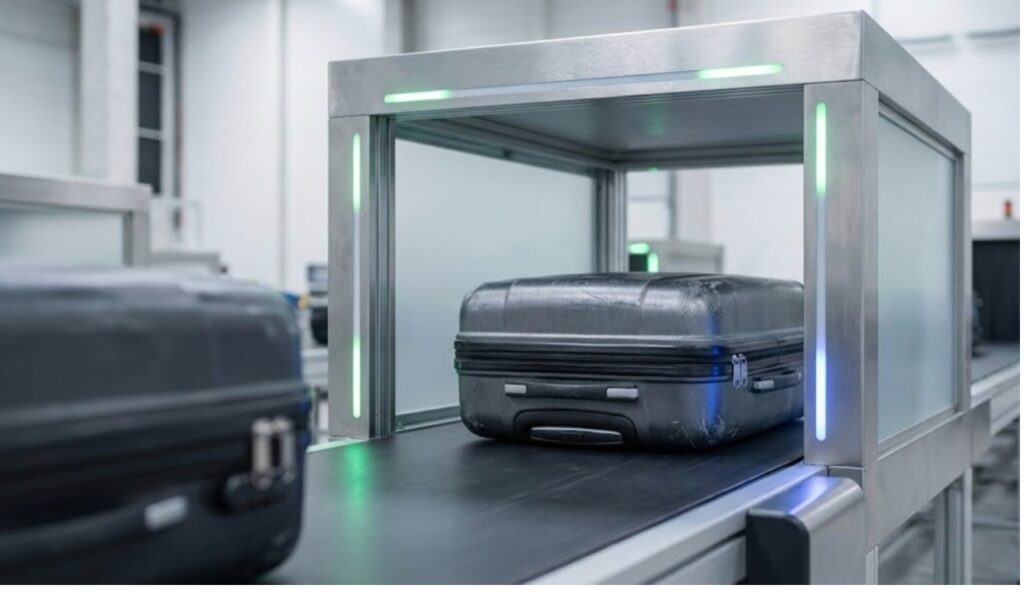

To solve the problem, we must first dissect the anatomy of the baggage chain. The workflow—Check-in, Scanning, Sorting, Loading, and Tracking—looks linear on paper, but in a live airport environment, it is dynamic and chaotic.

The traditional pain points are well known: physical bottlenecks at transfer points, misrouting due to poor scan rates, and the catastrophic risk of unplanned downtime. However, the regulatory landscape is changing how we address these.

IATA Resolution 753 has been a game-changer. It mandates that IATA members track baggage at four critical custody changes:

- Acceptance: When the airline takes the bag.

- Load: When the bag is delivered to the aircraft.

- Transfer: During custody changes between carriers.

- Arrival: Upon delivery to the passenger.

Compliance with Resolution 753 isn’t just about ticking boxes; it’s about data visibility. This is why we are seeing a massive migration from optical barcode scanning to RFID technology. In our deployments, we consistently see that RFID offers read rates vastly superior to optical scanning, especially when bags are moving at high speeds on a conveyor or are oriented irregularly.

Siwun’s Engineering Approach: Precision Meets Flexibility

At Siwun, we don’t believe in “one-size-fits-all” automation. An airport is a living organism with unique spatial constraints and flow peaks. Our approach to Airport Operations Solutions focuses on four engineering pillars:

- Flexible Deployment for Complex Layouts

Legacy airports often struggle to retrofit modern automation into existing terminals. We address this with adaptable infrastructure. Our telescopic belt conveyors and modular belt systems are designed to maximize throughput without requiring a complete terminal redesign. Whether it is an intake line or a final loading bay, the equipment must mold to the airport, not the other way around.

- High-Precision Sorting Algorithms

Speed means nothing without accuracy. A fast sorter that misdirects 1% of bags is a liability. By synchronizing the physical speed of the diversion mechanism with real-time destination data, we ensure high throughput is maintained without compromising sorting purity. This is critical for tight connection windows where every second counts.

- End-to-End Visibility (WCS + RFID)

Hardware is the muscle, but software is the brain. Our solutions integrate a robust Warehouse Control System (WCS) that acts as the nervous system of the baggage hall. By integrating RFID data directly into the WCS, we provide airports with granular, end-to-end tracking. This fulfills the IATA 753 mandate and provides the data foundation needed to predict bottlenecks before they occur.

- Smart Maintenance and Uptime

The most expensive machine is the one that isn’t working. Drawing from our experience in high-volume Asia Air Cargo Hubs, we know that downtime is unacceptable. We have moved beyond “break-fix” models to predictive maintenance. Through remote monitoring and modular service designs, our systems allow engineering teams to identify wear and tear on components before failure happens, drastically reducing maintenance windows and keeping the baggage flowing.

Conclusion

The ultimate goal of automation is “frictionless travel.” Passengers today are more data-hungry than ever. Research indicates that 83% of travelers want real-time flight status updates, and 45% specifically demand notifications about their baggage. They want to know their bag has arrived before they even reach the carousel.

To achieve this, the technology must effectively become invisible. It should work so seamlessly that the passenger never has to worry about the mechanics of the journey. Automation redefines the role of airport staff, moving them away from heavy lifting and repetitive tasks toward high-value passenger service.

Partner with Siwun to bring intelligence and reliability to your airport operations. Let us help you engineer a baggage system that turns a logistical challenge into a competitive advantage.