In the face of soaring e-commerce volumes and relentless pressure to accelerate fulfillment, global logistics, e-commerce, and postal operators are re-evaluating their warehouse operations. Manual sorting processes have become a significant bottleneck, leading to delays, errors, and rising costs. The integration of intelligent conveying systems is no longer a futuristic concept but a strategic imperative for staying competitive. This blog explores five key, data-supported benefits of implementing a smart conveyor sorting solution and demonstrates how it directly addresses core industry pain points.

1. Dramatically Increase Throughput and Efficiency

The primary challenge for any growing operation is scaling order fulfillment capacity without a proportional increase in space or labor. Smart conveyor systems are engineered to move a high volume of items 24/7, creating a seamless flow from receiving to dispatch.

The efficiency gains are tangible. For instance, after implementing an automated sortation system, Alliance Entertainment reported processing up to 2,100 items per hour. By automating package movement, these systems eliminate the time wasted on manual carrying and walking. This ensures your sorting in warehouse operations keep pace with inbound and outbound demands, particularly during peak seasons, ultimately allowing you to handle more orders and grow your business without operational friction.

2. Achieve Significant Reductions in Labor Costs and Errors

Reliance on manual labor for repetitive sorting in warehouse tasks is not only costly but also prone to inconsistencies. Automated handling solutions directly address this by taking over the most physically demanding and monotonous jobs.

The real-world impact on labor is profound. The same case study with Alliance Entertainment showed a 90% reduction in labor effort for sortation, cutting the time required from 12 man-hours to just 1.2 man-hours. This massive reduction allows you to re-deploy your existing staff to more value-added tasks like quality control and exception handling. Furthermore, automation drastically cuts down on mis-sorts and incorrect scans, leading to more reliable order fulfillment and higher customer satisfaction.

3. Unlock Unmatched Sorting Accuracy and Flexibility

Accuracy is the cornerstone of modern logistics, where a single mis-sorted parcel can lead to costly reverse logistics and damage to your brand’s reputation. Advanced smart sorting systems utilize sophisticated scanning and AI to direct each item to its correct destination with precision often exceeding 99.9%.

A critical feature that enables this high accuracy and flexibility is automatic parcel singulation. This process transforms a chaotic, overlapping stream of packages into a single-file, evenly spaced line. Effective sorting is the foundation for optimal scanning and sorting, ensuring the system can adapt to a wide variety of items, from small envelopes to oversized products. This adaptability was a key factor for Alliance Entertainment, whose system can now process 98% of its diverse inventory, including oversized vinyl records and uniquely shaped collectibles.

4. Gain a Scalable Solution for Future Growth

The logistics landscape is constantly evolving, and your operations need to be agile. Modern intelligent conveying systems are inherently modular and scalable. As your business expands or your product mix changes, these systems can be reconfigured or extended without a complete overhaul. This scalability is crucial in an era where global e-commerce package volume is expected to continue its rapid growth.

Investing in a scalable automated handling solutions platform means you can start with what you need today and expand capabilities as your business grows, protecting your investment and ensuring long-term viability.

5. Improve Workplace Safety and Unlock Data Insights

A warehouse reliant on manual carts and heavy lifting poses inherent safety risks. Automated handling solutions create a more organized and predictable environment by confining rapid movement to the conveyor lines, thereby reducing workplace accidents.

Moreover, these systems are data powerhouses. They generate real-time analytics on flow rates, bottlenecks, and system performance. This data provides the insights needed for continuous process improvement and informed strategic planning, allowing you to optimize your entire operation proactively .

Conclusion

The transition to automation is an investment that pays for itself through unparalleled efficiency, accuracy, and cost savings. The data is clear: businesses are achieving dramatic reductions in labor, significant gains in throughput, and new levels of operational flexibility.

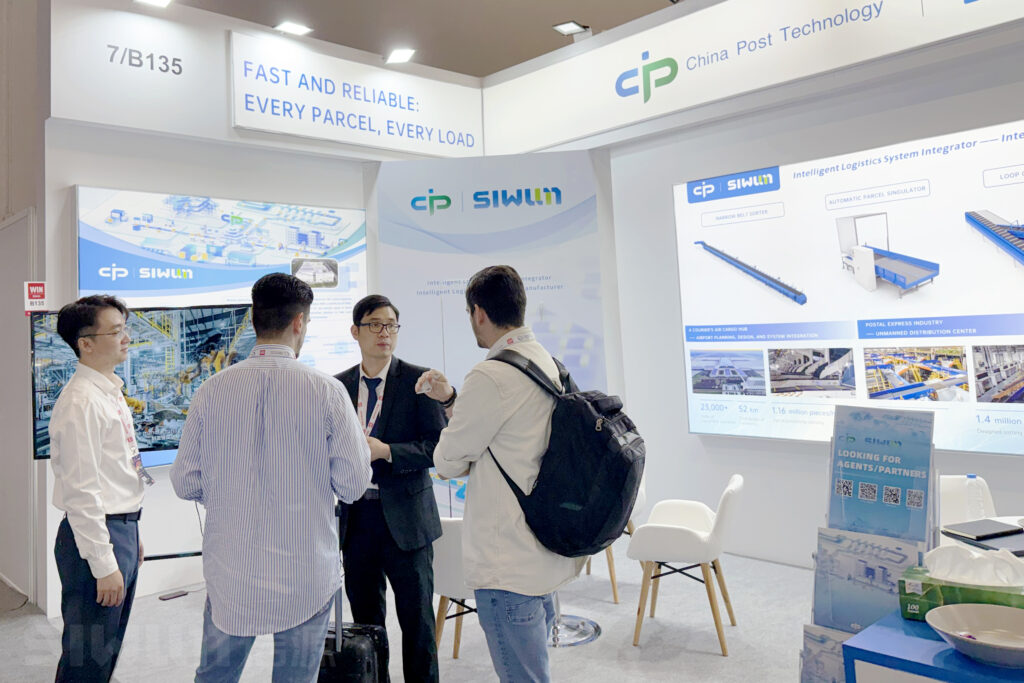

At SIWUN, we specialize in providing intelligent conveying systems, including high-speed cross-belt sorters and tilt-tray sorters, designed to tackle the very challenges you face daily. Our automated handling solutions are engineered to optimize your sorting in warehouse processes, ensuring your operation is not just competitive, but leading the pack.

Reference

https://www.mmh.com/article/productivity_solutions_alliance_entertainment_boosts_warehouse_efficiency_with_opex_sure_sort_x_automation/technology

https://www.siwun.cn/wp-content/uploads/2024/05/AUTOMATIC-PARCEL-SINGULATOR.pdf