The global aviation industry’s explosive growth, with passenger traffic reaching 9.5 billion in 2024 and projected to hit 9.9 billion in 2025[1], is placing unprecedented strain on airport baggage handling systems (BHS). While technology has improved the mishandling rate per passenger, this progress is offset by the sheer volume of travelers. This “Scale vs. Rate” paradox creates a staggering financial burden, costing the industry an estimated $5 billion in 2024 alone[2] and making BHS efficiency a critical strategic imperative.

Core Sorting Equipment Technologies

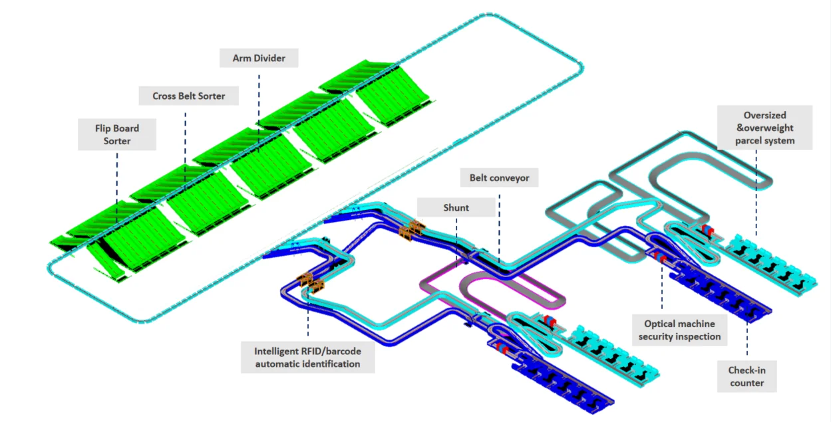

The heart of any advanced BHS is its automated sortation technology, which determines the system’s overall speed and accuracy. Three key technologies define the core of a baggage handling system.

- Cross-Belt Sorters: These systems are becoming a leading technology because they are purpose-built for the unique demands of airport luggage. A cross-belt sorter uses a loop of carts, each with its own small conveyor belt, to gently and precisely discharge bags at the correct location. This method is ideal for handling the diverse sizes and shapes of passenger luggage and allows for a high density of sort destinations, making it perfect for space-constrained terminals.

- Vertical Sorters: In the complex, multi-level environment of a modern airport, vertical sorters are essential for managing space and ensuring operational continuity. A Vertical Sortation Unit (VSU) uses a pivoting paddle conveyor to divert a single stream of bags to one of two different levels. This is critical for creating resilient and redundant pathways, especially for separating cleared and rejected bags in security screening zones.

- Robotic Sorting Systems: As an alternative to large, fixed conveyor systems, some airports are exploring flexible and scalable solutions using fleets of sorting robots. These robots can be deployed in dynamic sorting stations that are easily reconfigured or expanded to meet changing demands, offering a new level of adaptability in BHS design.

Essential Conveying Systems

Before a bag can be sorted, it must be effectively transported. Innovations in the conveyance, or the airport baggage belt, focus on reliability, precision, and safety.

- Curve Conveyors: A simple 90-degree turn can be a major point of failure in a BHS, risking jams and bag reorientation that makes tags unreadable. Modern power curve conveyors are engineered for smooth, high-speed directional changes. They use specialized belt fabrics and tapered drums to ensure perfect tracking, preventing system errors and damage.

- Singulation Systems: The journey of every bag begins with singulation—the critical process of transforming a chaotic bulk flow of luggage into an organized, single-file stream. This step is essential for the accuracy of all downstream automated processes, like scanning and sorting. Modern singulators use a combination of multi-speed belts, advanced sensors, and angled rollers to gently separate and align each item for precise handling.

- Telescopic Belt Conveyors: The final stage of loading bags onto an aircraft is one of the most physically demanding and injury-prone jobs in an airport. Telescopic belt conveyors are a transformative solution, extending directly into the aircraft hold or container. By bringing the conveyor to the point of stacking, they dramatically reduce manual carrying and lifting, increasing productivity by up to 30% while significantly improving worker safety.

Siwun’s Intelligent Baggage Handling Solution

At Siwun, we provide a comprehensive, intelligent baggage handling solution that translates advanced theory into tangible performance. Our system is engineered around a core of powerful, proven hardware and orchestrated by intelligent software to solve the core challenges facing modern airports.

1. High-Speed, High-Accuracy Sorting Engine

The heart of our solution is the Siwun Cross-Belt Sorter, a key component that drives the system’s overall speed and precision. This is not just a concept; it is a proven workhorse designed for the most demanding logistics environments.

- Unmatched Performance: Capable of operating at speeds up to 2.2 m/s with a theoretical sorting efficiency of 13,200 pieces per hour (pph), our sorter provides the raw throughput needed to handle peak travel seasons without bottlenecks.

- Precision Sorting: With a barcode scanning and sorting accuracy of ≥ 99.9%, it forms the reliable foundation for all downstream processes. This precision minimizes missorts and is the first step in our automated error correction and reflighting protocol, which can intelligently reroute bags without manual intervention.

- Data-Driven Intelligence: This high-performance hardware is governed by our advanced High-Level Control (HLC) software. By integrating IoT sensors for predictive maintenance, we ensure the mechanical core of your BHS—the sorter itself—maintains maximum uptime.

2. Ergonomic and Efficient End-to-End Handling

Our solution extends beyond the central sorting hall to address critical “first-mile” and “last-mile” challenges. The final stage of loading bags, a major source of injuries and inefficiency, is transformed by the SIWUN Logistics Telescopic Belt Conveyor.

- Flexible and Safe Loading: Designed to extend directly into an aircraft hold or container, this conveyor features adjustable length and a hydraulic lift for variable height. It brings the conveyor’s end-point directly to the baggage handler, eliminating hazardous manual carrying and lifting.

- Productivity Boost: By streamlining the loading and unloading process, this system not only significantly improves worker safety but also boosts productivity by up to 30%. Its robust design can handle goods of various weights and sizes, making it a versatile tool for any ground operation.

3. Seamless Integration for Uncompromised Security

A modern BHS must be perfectly synchronized with security systems. We design our solutions for deep integration with multi-level hold baggage screening (HBS) systems. Using components like Vertical Sortation Units (VSUs), we create optimized, compact layouts that ensure a resilient and compliant pathway for separating cleared and rejected baggage.

4. A Holistic Approach for All Baggage Types

We recognize that not all luggage fits the standard. Our comprehensive BHS design incorporates dedicated processes and areas to handle out-of-gauge items, such as large sports equipment or fragile instruments. This specialized handling prevents damage, reduces jams in the main system, and ensures all baggage is managed with appropriate care.

5. Future-Proof Modularity and Scalability

Our systems are built on a philosophy of modular hardware and flexible, open-platform software. This allows our BHS to be perfectly scaled to the needs of any airport, from smaller regional hubs to massive international gateways. This ensures that as passenger traffic grows, the system can be easily expanded and adapted, protecting the airport’s investment for the long term.

Conclusion

As passenger volumes continue to soar, the efficiency of baggage handling has become central to an airport’s financial performance, competitive position, and customer loyalty. Incremental improvements are no longer sufficient. The path forward is built on a clear strategy of investing in intelligent and automated solutions.

To stay competitive, airport operators must embrace scalable hardware like cross-belt sorters, robust tracking technologies, and intelligent automation that reduces manual strain and human error. Success requires radical collaboration, open data sharing between airports, airlines, and ground handlers, and a forward-looking mindset. By exploring and implementing intelligent and holistic solutions like those offered by Siwun, airports can transform a source of cost and anxiety into a seamless, transparent, and value-adding part of the modern travel experience.

References

[1] https://www.aviationturkey.com/en/content/aci-world-forecasts-9-9-billion-passengers-in-2025-amid-shifting-market-dynamics-1159

[2] https://www.webwire.com/ViewPressRel.asp?aId=339698