If you ask most e-commerce executives where they are losing money, they often point to “last-mile delivery” or rising ad costs. They are usually wrong.

The single biggest profit leak in modern e-commerce isn’t getting the product to the customer. Reverse logistics is where profit margins go to die. Retailers estimate that 16.9% of their annual sales will be returned. In high-touch categories like apparel, that number often surges past 30%.

For years, retailers lowered the barrier to purchase by offering seamless, free returns. Now, we are paying the price. The concept of reverse logistics has grown alongside e-commerce, but for many, the infrastructure hasn’t kept up.

If your strategy for what is reverse logistics relies on folding tables and manual labor, you aren’t just losing operational efficiency—you are bleeding recoverable capital.

The “Piles of Pain”: Why Manual Processes Fail

Walk into a non-automated distribution center (DC), and you can physically see the problem. We call it the “Pile of Pain.”

In a manual setup, returns pile up in cages or corners because the process is inherently irregular and unpredictable. Unlike outbound orders, which are scheduled and batched, returns arrive randomly. They are messy. One box might contain a pristine jacket; the next, a broken blender; the third, a fraudulent return filled with old bricks.

What is reverse logistics in supply chain management if not the complex art of untangling this mess? The complexity includes processing customer credits, collecting and repairing defective items, and managing waste or disposal.

The economic challenge here is brutal. Retailers are trapped between satisfying consumer demand for “instant refunds” and the skyrocketing labor costs required to inspect, verify, and sort these items. When handled manually, the process is slow, error-prone, and expensive. But the real cost isn’t just the labor wages—it’s the lost product value as inventory sits idle, depreciating on a warehouse floor.

The Solution: Bringing Order to Chaos with Automation

To fix this, we need to stop treating returns as an afterthought and start treating them with the same discipline as outbound fulfillment. This is how to improve reverse logistics: by deploying automation that enforces standardized decision-making.

Here is how a modern, automated reverse logistics workflow functions, utilizing advanced systems like those developed by Siwun.

Step 1: Automated Inbound & Identification

The chaos ends at the dock door. Instead of a worker manually reading a label and guessing the SKU, parcels are scanned immediately. Automated systems instantly identify the order in the Warehouse Management System (WMS). Labor-saving technologies, such as AI and robotics, are now being adopted to streamline this initial handshake, cutting labor costs from minute one.

Step 2: Intelligent Sorting (The Siwun Standard)

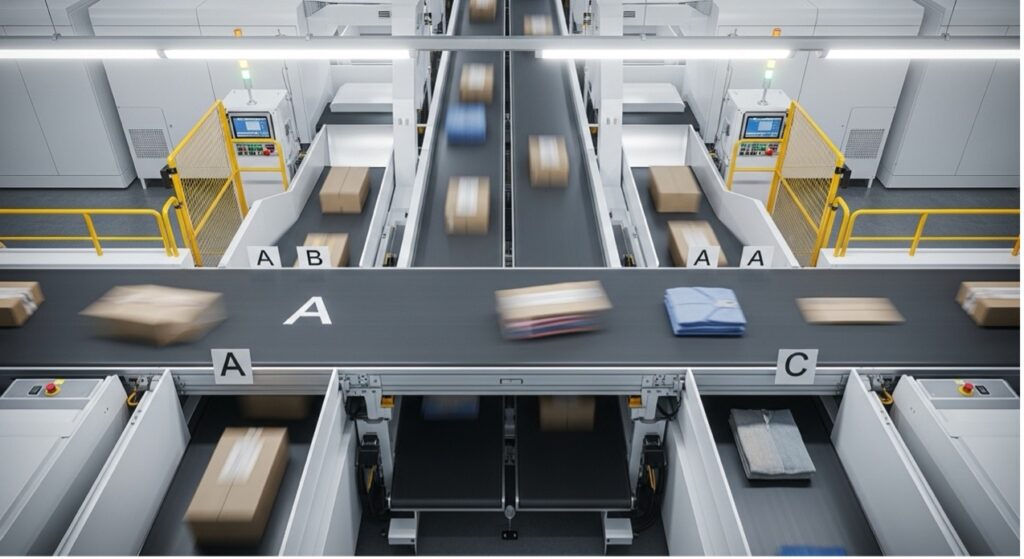

Once identified, the item enters the sorting phase. This is where the bottleneck usually occurs, and where technology like Siwun’s Automated Sorters (utilizing Wheel or Cross-Belt technology) creates the biggest efficiency jump.

Instead of relying on human judgment, the Siwun system diverts items based on strict WMS rules, effectively automating the ABC Inventory Classification logic:

- Lane 1: “Grade A” (The Gold Mine). These are items in perfect condition. In the ABC classification system, these correspond to “Class A” items—typically 10-20% of SKUs that account for 50-70% of inventory value. The sorter identifies these high-value items and routes them for instant restocking. Speed here is critical for value recovery.

- Lane 2: “Grade B” (The Fixer-Uppers). Items needing repackaging or minor repairs. The system automatically diverts them to specific workstations, separating them from the high-velocity flow.

- Lane 3: “Grade C” (Clearance/Outlet). Like “Class C” inventory (60-70% of quantity but only 10-30% of value), these are lower-value items managed with looser controls. The sorter routes these directly to liquidation or discount channels.

- Lane 4: “Grade D” (End of Life). This aligns with the waste management aspect of reverse logistics. Siwun’s sorters ensure obsolete or “Grade D” stock is immediately separated for recycling or destruction, preventing it from clogging valuable storage space.

Step 3: Rapid Restocking

The ultimate goal of this automation is Rapid Restocking. In a manual warehouse, a returned “Grade A” dress might sit in a bin for weeks. With a system like Siwun’s, that same dress can be received, inspected, sorted, and back in sellable inventory in hours, not weeks. This speed directly impacts Inventory Turnover—a measure of how many times you sell and replace inventory in a year.

The Value: It’s About GMROII, Not Just Labor Savings

To truly understand the value, we must look at GMROII (Gross Margin Return on Inventory Investment). GMROII measures both inventory profitability and productivity. It answers the question: For every dollar invested in inventory, how many dollars of gross margin are we generating?

The formula for GMROII heavily relies on Inventory Turnover. By automating reverse logistics with high-speed sorting:

- Faster Turn: You increase the availability of your “Class A” inventory without buying new stock.

- Higher Profitability: Industry analysis suggests that increasing inventory turnover by just one time can be equivalent to increasing your discount rate by 6 percentage points. Speed protects price integrity.

Furthermore, efficient sorting supports the circular economy. By ensuring resources and products remain in use for as long as possible, solutions like Siwun’s don’t just save money; they build a sustainable supply chain strategy.

Conclusion

Reverse logistics is no longer just the “cost of doing business.” It is a strategic battlefield.

Retailers who continue to rely on manual sorting will find their margins eroded. Those who adopt automation solutions—like the intelligent sorting systems from Siwun—will unlock hidden capital, turning their returns department from a cost center into a value recovery engine.

Is your warehouse bleeding profit through returns? It might be time to rethink your reverse logistics workflow. Let’s discuss how Siwun’s automation can improve your GMROII this quarter.