Copyright © 2024 Guangdong Siwun Logistics Equipment Co., Ltd., All rights reserved.

Telescopic Belt Conveyor is designed to extend and retract, allowing for flexible adjustment of the conveyor length to adapt to different working spaces and material handling requirements.

Maximum Capacity Sorting Accuracy Wide Range

Up to 6,500 ≥99% success rate Handles

pcs/hour 1mm-700mm height

| Belt width | 650mm/800mm/1000mm(Can be customized) |

| Conveying speed | V=25-45m/min(Speed control with frequency conversion) |

| Load | Conventional 60Kg/m², Heavy cargo 80Kg/m² |

| Power supply | 380V±10% 50Hz three-phase five-wire system |

Telescopic Belt Conveyor is designed to extend and retract, allowing for flexible adjustment of the conveyor length to adapt to different working spaces and material handling requirements.

Maximum Capacity Sorting Accuracy Wide Range

Telescopic Belt Conveyor is designed to extend and retract, allowing for flexible adjustment of the conveyor length to adapt to different working spaces and material handling requirements.

Maximum Capacity Sorting Accuracy Wide Range

Up to 6,500 ≥99% success rate Handles

pcs/hour 1mm-700mm height

The Telescopic Belt Conveyor by SIWUN Logistics is typically the front or rear equipment in material transfer processes, used for loading and unloading goods between trucks and transfer yards. It is also common in sorting centers and distribution facilities to move goods between sorting stages, as part of our sorting conveyor solutions.

It extends and retracts to accommodate varying distances, ensuring efficient and flexible operations in warehouses and logistics hubs.

Flexible Expansion: This conveyor features an expansion mechanism that allows the movable section to freely extend along the length, enhancing versatility.

Customizable Loading and Unloading: Tailor the direction of cargo transport to meet specific needs.

Adjustable Telescopic Length: Effortlessly adjust the conveyor’s length to meet your specific needs.

Height Adjustable: Equippe

Easy to Operate and Maintain: The Telescopic Belt Conveyor is simple to operate with intuitive controls. Its structure is relatively simple, making it easy to maintain and reducing maintenance costs.

d with a hydraulic lift, the conveyor can be adjusted to various heights effortlessly.

A Telescopic Belt Conveyor is an extendable conveyor system that can extend and retract its length based on operational needs. Unlike fixed sorting conveyors, our telescoping conveyor features multiple nested sections that slide in and out, allowing the conveyor to adapt its reach dynamically.

These equipment are primarily used in warehouse loading docks, distribution centers, and logistics facilities for truck loading and unloading operations. The key benefits include:

Our telescopic conveyors can operate in both manual and automatic modes depending on the model and customer requirements. The extension mechanism uses a powered drive system that smoothly extends or retracts the nested conveyor sections.

Operators can control the extension length through a simple control panel, adjusting the reach to match the specific loading position. Some advanced models feature sensors that can automatically adjust extension based on vehicle position, ensuring optimal placement for efficient material handling.

The Telescopic Belt Conveyor by SIWUN Logistics is typically the front or rear equipment in material transfer processes, used for loading and unloading goods between trucks and transfer yards. It is also common in sorting centers and distribution facilities to move goods between sorting stages, as part of our sorting conveyor solutions.

It extends and retracts to accommodate varying distances, ensuring efficient and flexible operations in warehouses and logistics hubs.

The Telescopic Belt Conveyor by SIWUN Logistics is typically the front or rear equipment in material transfer processes, used for loading and unloading goods between trucks and transfer yards. It is also common in sorting centers and distribution facilities to move goods between sorting stages, as part of our sorting conveyor solutions.

It extends and retracts to accommodate varying distances, ensuring efficient and flexible operations in warehouses and logistics hubs.

Flexible Expansion: This conveyor features an expansion mechanism that allows the movable section to freely extend along the length, enhancing versatility.

Customizable Loading and Unloading: Tailor the direction of cargo transport to meet specific needs.

Adjustable Telescopic Length: Effortlessly adjust the conveyor’s length to meet your specific needs.

Height Adjustable: Equippe

Easy to Operate and Maintain: The Telescopic Belt Conveyor is simple to operate with intuitive controls. Its structure is relatively simple, making it easy to maintain and reducing maintenance costs.

d with a hydraulic lift, the conveyor can be adjusted to various heights effortlessly.

A Telescopic Belt Conveyor is an extendable conveyor system that can extend and retract its length based on operational needs. Unlike fixed sorting conveyors, our telescoping conveyor features multiple nested sections that slide in and out, allowing the conveyor to adapt its reach dynamically.

These equipment are primarily used in warehouse loading docks, distribution centers, and logistics facilities for truck loading and unloading operations. The key benefits include:

Our telescopic conveyors can operate in both manual and automatic modes depending on the model and customer requirements. The extension mechanism uses a powered drive system that smoothly extends or retracts the nested conveyor sections.

Operators can control the extension length through a simple control panel, adjusting the reach to match the specific loading position. Some advanced models feature sensors that can automatically adjust extension based on vehicle position, ensuring optimal placement for efficient material handling.

Flexible Expansion: This conveyor features an expansion mechanism that allows the movable section to freely extend along the length, enhancing versatility.

Customizable Loading and Unloading: Tailor the direction of cargo transport to meet specific needs.

Adjustable Telescopic Length: Effortlessly adjust the conveyor’s length to meet your specific needs.

Height Adjustable: Equippe

Easy to Operate and Maintain: The Telescopic Belt Conveyor is simple to operate with intuitive controls. Its structure is relatively simple, making it easy to maintain and reducing maintenance costs.

d with a hydraulic lift, the conveyor can be adjusted to various heights effortlessly.

A Telescopic Belt Conveyor is an extendable conveyor system that can extend and retract its length based on operational needs. Unlike fixed sorting conveyors, our telescoping conveyor features multiple nested sections that slide in and out, allowing the conveyor to adapt its reach dynamically.

These equipment are primarily used in warehouse loading docks, distribution centers, and logistics facilities for truck loading and unloading operations. The key benefits include:

Our telescopic conveyors can operate in both manual and automatic modes depending on the model and customer requirements. The extension mechanism uses a powered drive system that smoothly extends or retracts the nested conveyor sections.

Operators can control the extension length through a simple control panel, adjusting the reach to match the specific loading position. Some advanced models feature sensors that can automatically adjust extension based on vehicle position, ensuring optimal placement for efficient material handling.

| Belt width | 650mm/800mm/1000mm(Can be customized) |

| Conveying speed | V=25-45m/min(Speed control with frequency conversion) |

| Load | Conventional 60Kg/m², Heavy cargo 80Kg/m² |

| Power supply | 380V±10% 50Hz three-phase five-wire system |

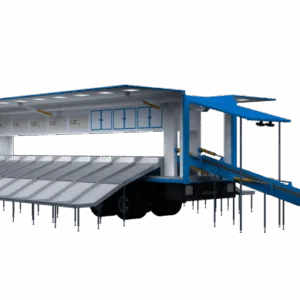

The SIWUN Mobile Sorting Unit is an innovative logistics solution that integrates a high-speed intelligent sorting system onto a purpose-built specialty vehicle platform. Featuring mobile deployment capabilities and ready-to-use functionality upon arrival, this unit not only supplements seasonal sorting capacity but also enables the relocation of sorting operations to front-end locations. It efficiently manages the surge in logistics sorting demands that occur during scenarios such as fresh produce harvests, e-commerce sales events, and direct shipments of specialty economy goods—significantly enhancing logistics operational efficiency and agility while lowering operational costs.

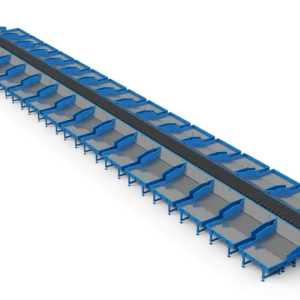

The Siwun NC Straight Cross-belt Sorter is configured with two key operational features, working together to ensure stable sorting:

Manual loading mode: This is the way staff feed parcels into the system—simple to operate, with no complex steps for on-site teams.

"One cart for one item" operating principle: Every parcel is matched to its own dedicated sorting cart (not shared with other items)—this is the core design that prevents workflow issues.

Single-Level Configuration;

Electrically Operated Bilateral Slide-Out System;

Equipped with LED Screen