Copyright © 2024 Guangdong Siwun Logistics Equipment Co., Ltd., All rights reserved.

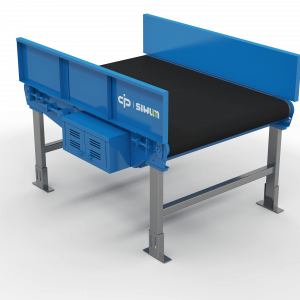

| Strip Belt Merge is a kind of equipment widely used in conveying and sorting system. |

| Parcel Weight: | ①Dynamic:60kg/㎡ ②Static: 100kg/㎡Speed:30-150m/min Curve Angle: 90° |

| Effective Transmission Width: | 1060mm、1260mm、1460mm |

| Turning Radius: | 1700mm |

| Standard Drop Height: | 600mm |

| Strip Belt Merge is a kind of equipment widely used in conveying and sorting system. |

| Strip Belt Merge is a kind of equipment widely used in conveying and sorting system. |

With the wheel sorter, theshunt conveying system is formed to realize the function of goods shunt, With belt conveyor to form a conflu-ence conveying system to achieve the function of goods confluence.

It is used to transport cartons, pallets, plastic boxes and other goods in split or confluence direction.Bulk materi.

als, flat parts, small items or irregular items should be placed on the tray or turnover box.

| Flexible Layout for Bidirectional Function It supports flexible arrangement on either the left or right side of the balance wheel shunt. This adaptive layout design directly enables a bidirectional shunt/sorting function, allowing the system to adapt to diverse on-site layout requirements (e.g., left-side shunt for inbound goods, right-side shunt for outbound goods) without major structural modifications—enhancing overall workflow flexibility. Modular Design for Easy Assembly The system is composed of multiple standard series modules, which are fixed side by side on the frame in accordance with corresponding combination rules. This standardized modular design simplifies assembly: modules can be quickly combined or adjusted based on sorting scale (e.g., adding modules for expanded capacity, reducing modules for small spaces) and ensures consistent quality across components—lowering customization costs and shortening deployment time. Rear-Motor Driven for Stable Operation It adopts a “motor-after-drum” drive structure: the motor drives the narrow belts of all unit modules via the drum. This power transmission design ensures uniform force on the narrow belts, avoiding uneven speed or belt slippage caused by scattered drives. As a result, the system maintains stable, continuous operation even during high-throughput sorting—aligning with the core advantage of “stable operation” highlighted in previous technical descriptions. |

With the wheel sorter, theshunt conveying system is formed to realize the function of goods shunt, With belt conveyor to form a conflu-ence conveying system to achieve the function of goods confluence.

It is used to transport cartons, pallets, plastic boxes and other goods in split or confluence direction.Bulk materi.

als, flat parts, small items or irregular items should be placed on the tray or turnover box.

With the wheel sorter, theshunt conveying system is formed to realize the function of goods shunt, With belt conveyor to form a conflu-ence conveying system to achieve the function of goods confluence.

It is used to transport cartons, pallets, plastic boxes and other goods in split or confluence direction.Bulk materi.

als, flat parts, small items or irregular items should be placed on the tray or turnover box.

| Flexible Layout for Bidirectional Function It supports flexible arrangement on either the left or right side of the balance wheel shunt. This adaptive layout design directly enables a bidirectional shunt/sorting function, allowing the system to adapt to diverse on-site layout requirements (e.g., left-side shunt for inbound goods, right-side shunt for outbound goods) without major structural modifications—enhancing overall workflow flexibility. Modular Design for Easy Assembly The system is composed of multiple standard series modules, which are fixed side by side on the frame in accordance with corresponding combination rules. This standardized modular design simplifies assembly: modules can be quickly combined or adjusted based on sorting scale (e.g., adding modules for expanded capacity, reducing modules for small spaces) and ensures consistent quality across components—lowering customization costs and shortening deployment time. Rear-Motor Driven for Stable Operation It adopts a “motor-after-drum” drive structure: the motor drives the narrow belts of all unit modules via the drum. This power transmission design ensures uniform force on the narrow belts, avoiding uneven speed or belt slippage caused by scattered drives. As a result, the system maintains stable, continuous operation even during high-throughput sorting—aligning with the core advantage of “stable operation” highlighted in previous technical descriptions. |

| Flexible Layout for Bidirectional Function It supports flexible arrangement on either the left or right side of the balance wheel shunt. This adaptive layout design directly enables a bidirectional shunt/sorting function, allowing the system to adapt to diverse on-site layout requirements (e.g., left-side shunt for inbound goods, right-side shunt for outbound goods) without major structural modifications—enhancing overall workflow flexibility. Modular Design for Easy Assembly The system is composed of multiple standard series modules, which are fixed side by side on the frame in accordance with corresponding combination rules. This standardized modular design simplifies assembly: modules can be quickly combined or adjusted based on sorting scale (e.g., adding modules for expanded capacity, reducing modules for small spaces) and ensures consistent quality across components—lowering customization costs and shortening deployment time. Rear-Motor Driven for Stable Operation It adopts a "motor-after-drum" drive structure: the motor drives the narrow belts of all unit modules via the drum. This power transmission design ensures uniform force on the narrow belts, avoiding uneven speed or belt slippage caused by scattered drives. As a result, the system maintains stable, continuous operation even during high-throughput sorting—aligning with the core advantage of "stable operation" highlighted in previous technical descriptions. |

| Parcel Weight: | ①Dynamic:60kg/㎡ ②Static: 100kg/㎡Speed:30-150m/min Curve Angle: 90° |

| Effective Transmission Width: | 1060mm、1260mm、1460mm |

| Turning Radius: | 1700mm |

| Standard Drop Height: | 600mm |

The Siwun Narrow-Belt Sorter specifically incorporates a "cutting-edge high-precision dimension measurement system," which is specially designed to overcome the aforementioned challenges in sorting large and heavy items and possesses the ability to solve problems efficiently.

Dual-Level Configuration;

Electrically Operated Bilateral Slide-Out System

SIWUN belt conveyor provides a stable and reliable surface for transporting materials, significantly reducing the risk of spills or damage during transit, which is widely used in industrial conveyor systems.

Energy-Efficient Length Three-Tier

Precision Speed

0.75KW-4KW 1000mm-18000mm 30m/min-150m/min