Copyright © 2024 Guangdong Siwun Logistics Equipment Co., Ltd., All rights reserved.

Static DWS Sorter plays a crucial role in optimizing product sortation processes in modern warehouses.

SIWUN Logistics’ Advanced Sorting Solutions–Static DWS Sorter

Processing Capacity High Precision Package Weigh

Up to 3,000 Automatic recognition From 0.06kg to 15kg

packages per hour and sorting

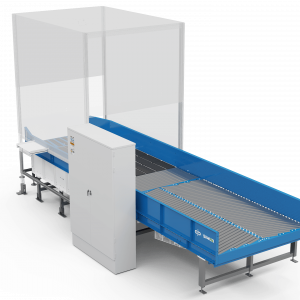

Our Static DWS Sorter is dimensional weight scanner, engineered as a fast sorter for rapid package handling. Once it weighs and scans parcels, the integrated DWS system automatically identifies and analyzes data to direct packages along the most efficient route.

Compact and Flexible: The sorter is compact and can be quickly adapted to each use scenario.

Smart and Convenient: It reads codes, weighs packages and distribute them to multiple channels.

Safe and Reliable: CPA certified.

Easy Maintenance: Due to its modular design, the sorter is easy to operate and maintain.

| Size Range of Packages Can Be Handled | |

| Package Weight | From 0.06kg to 15kg |

| Package Size | Face Straight Up≤450mm |

| Maximum Package Size | 500mm X 400mm |

| Production Efficiency | Efficiency to send and receive by human-machine cooperation ≥ 1400 pcs/hour |

A static DWS sorter is a parcel sorting system that integrates Dimensioning, Weighing, and Scanning functions (DWS) into one automated solution.

The DWS sorting equipment captures package dimensions, weight, and barcode information at a fixed scanning station, then automatically directs parcels to designated sorting destinations. This integrated approach streamlines the sorting process by combining multiple operations into a single workflow, reducing manual handling and improving data accuracy for logistics operations.

Our static DWS sorter is designed to be adaptable to various package sizes and weights commonly found in e-commerce and logistics operations. The key advantages of our sorting equipment include:

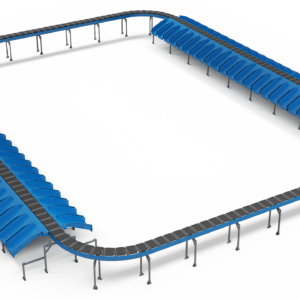

The Siwun Small-item Narrow-belt Sorter stands out in space-constrained settings with its highly compact structural design. This design is specifically engineered to maximize spatial efficiency, directly addressing the issue of limited operational area that plagues many parcel hub.

The Siwun Narrow-Belt Sorter specifically incorporates a "cutting-edge high-precision dimension measurement system," which is specially designed to overcome the aforementioned challenges in sorting large and heavy items and possesses the ability to solve problems efficiently.

Automatic Parcel Singulator effectively separates parcels, enabling subsequent automatic sorting machines to work more efficiently in warehouse sortation tasks.

Cross-Belt Sorter is a key component of our automated sorting systems, it ensures accurate and rapid sorting in warehouse and logistics operations.