Copyright © 2024 Guangdong Siwun Logistics Equipment Co., Ltd., All rights reserved.

The power roller conveyor includes straight roller conveyor, merge roller conveyor, curve roller conveyor ismainly com posed of electric roller, free roller, frame, leg, poly V-belt and other parts . lt is used for conveyinggoods with flat bottom surface.

| CarryingCapacity: | Max lode 50kg/section, Rated load 35kg/section |

| Electric Roller Power: | ①35W:speed 0.03~0.6m/s ②50W:speed 0.04~1.5m/s |

| Rated Voltage: | 24V |

| DrivingMode: | Poly V-belt |

| Roller Diameter: | 50mm |

The power roller conveyor includes straight roller conveyor, merge roller conveyor, curve roller conveyor ismainly com posed of electric roller, free roller, frame, leg, poly V-belt and other parts . lt is used for conveyinggoods with flat bottom surface.

The power roller conveyor includes straight roller conveyor, merge roller conveyor, curve roller conveyor ismainly com posed of electric roller, free roller, frame, leg, poly V-belt and other parts . lt is used for conveyinggoods with flat bottom surface.

The roller is fixed on the frame and connectedby a poly V-belt for low noise. The body side plate adopts standard carbonsteelmaterial to bend and form.which canadapt to high frequency use. The free rolleradopts elastic shaft and rollerbuckle for quick installation,easy maintenanceand replacement. In each section, photoelectric sensors arearrangedin the section position to facilitatepallet position tracking and stacking control.

It is suitable for conveying all kinds of boxes , bags, material boxes , and bulk materials , small items or iregular items need to be transported on the material box or turnover box. The merge roller conveyor and wheelsorter realizes shunt conveying of shallow pallets ; curve roller conveyor can change the direction of sh allowpallet conveying.

| Ring Network Layout The ring network adopts infrared communication, enabling the ring network to flexibly respond to sudden network anomalies. In case of an unexpected fault with a single cart or network cable at the site, the overall sorting operation status remains unaffected—this design minimizes risks to the greatest extent, ensuring uninterrupted sorting workflows. Stable Operation For the main ring drive, a high-efficiency and energy-saving linear synchronous motor is adopted; electric rollers are used for sorting. The narrow-belt sorting speed reaches 2.5 m/s, which not only achieves stable operation but also realizes efficient sorting—balancing energy conservation with high-performance sorting needs. System Modularity For small-scale sorting sites, narrow-belt sorting can be deployed, with multiple chute openings set on both sides. This modular design allows for maximum space utilization, making the system highly adaptable to limited-space scenarios without compromising sorting capacity. |

The roller is fixed on the frame and connectedby a poly V-belt for low noise. The body side plate adopts standard carbonsteelmaterial to bend and form.which canadapt to high frequency use. The free rolleradopts elastic shaft and rollerbuckle for quick installation,easy maintenanceand replacement. In each section, photoelectric sensors arearrangedin the section position to facilitatepallet position tracking and stacking control.

It is suitable for conveying all kinds of boxes , bags, material boxes , and bulk materials , small items or iregular items need to be transported on the material box or turnover box. The merge roller conveyor and wheelsorter realizes shunt conveying of shallow pallets ; curve roller conveyor can change the direction of sh allowpallet conveying.

The roller is fixed on the frame and connectedby a poly V-belt for low noise. The body side plate adopts standard carbonsteelmaterial to bend and form.which canadapt to high frequency use. The free rolleradopts elastic shaft and rollerbuckle for quick installation,easy maintenanceand replacement. In each section, photoelectric sensors arearrangedin the section position to facilitatepallet position tracking and stacking control.

It is suitable for conveying all kinds of boxes , bags, material boxes , and bulk materials , small items or iregular items need to be transported on the material box or turnover box. The merge roller conveyor and wheelsorter realizes shunt conveying of shallow pallets ; curve roller conveyor can change the direction of sh allowpallet conveying.

| Ring Network Layout The ring network adopts infrared communication, enabling the ring network to flexibly respond to sudden network anomalies. In case of an unexpected fault with a single cart or network cable at the site, the overall sorting operation status remains unaffected—this design minimizes risks to the greatest extent, ensuring uninterrupted sorting workflows. Stable Operation For the main ring drive, a high-efficiency and energy-saving linear synchronous motor is adopted; electric rollers are used for sorting. The narrow-belt sorting speed reaches 2.5 m/s, which not only achieves stable operation but also realizes efficient sorting—balancing energy conservation with high-performance sorting needs. System Modularity For small-scale sorting sites, narrow-belt sorting can be deployed, with multiple chute openings set on both sides. This modular design allows for maximum space utilization, making the system highly adaptable to limited-space scenarios without compromising sorting capacity. |

| Ring Network Layout The ring network adopts infrared communication, enabling the ring network to flexibly respond to sudden network anomalies. In case of an unexpected fault with a single cart or network cable at the site, the overall sorting operation status remains unaffected—this design minimizes risks to the greatest extent, ensuring uninterrupted sorting workflows. Stable Operation For the main ring drive, a high-efficiency and energy-saving linear synchronous motor is adopted; electric rollers are used for sorting. The narrow-belt sorting speed reaches 2.5 m/s, which not only achieves stable operation but also realizes efficient sorting—balancing energy conservation with high-performance sorting needs. System Modularity For small-scale sorting sites, narrow-belt sorting can be deployed, with multiple chute openings set on both sides. This modular design allows for maximum space utilization, making the system highly adaptable to limited-space scenarios without compromising sorting capacity. |

| CarryingCapacity: | Max lode 50kg/section, Rated load 35kg/section |

| Electric Roller Power: | ①35W:speed 0.03~0.6m/s ②50W:speed 0.04~1.5m/s |

| Rated Voltage: | 24V |

| DrivingMode: | Poly V-belt |

| Roller Diameter: | 50mm |

The Siwun Narrow-Belt Sorter specifically incorporates a "cutting-edge high-precision dimension measurement system," which is specially designed to overcome the aforementioned challenges in sorting large and heavy items and possesses the ability to solve problems efficiently.

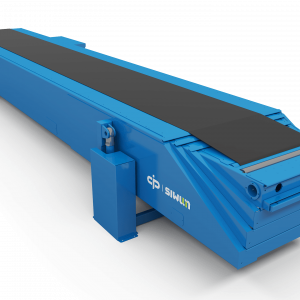

| Single-Level Configuration; Electrically Operated Bilateral Slide-Out System; Self-unloading from trailer to ground-ready operation |

Single-Level Configuration;

Electrically Operated Bilateral Slide-Out System;

Equipped with LED Screen

Telescopic Belt Conveyor is designed to extend and retract, allowing for flexible adjustment of the conveyor length to adapt to different working spaces and material handling requirements.

Maximum Capacity Sorting Accuracy Wide Range