Copyright © 2024 Guangdong Siwun Logistics Equipment Co., Ltd., All rights reserved.

The Siwun NC Straight Cross-belt Sorter is configured with two key operational features, working together to ensure stable sorting:

Manual loading mode: This is the way staff feed parcels into the system—simple to operate, with no complex steps for on-site teams.

“One cart for one item” operating principle: Every parcel is matched to its own dedicated sorting cart (not shared with other items)—this is the core design that prevents workflow issues.

The carts of the NC Small-item Straight Cross-belt Sorter are equipped with side guards, which prevent small items from shifting and falling during the NC sorting process—effectively ensuring stable and accurate sorting operation

Problem Focus: Inherent Challenges in Sorting Irregularly Shaped Items

Clearly identify the core pain points in the sorting process of irregularly shaped items—unlike standard regular-shaped items that are easy to handle, irregular ones (such as soft packages, plastic bags, document envelopes, cylinders, and spheres) often face two key issues:

Many traditional sorting systems lack the ability to adapt to diverse shapes, leading to frequent "sorting blind spots" (e.g., soft packages being crushed, cylindrical items rolling off conveyors);

Even when attempts are made to sort these items, inconsistent handling often causes delays, mis-sorts, or damage—becoming a major bottleneck for logistics facilities aiming to cover comprehensive parcel types.

Ring Network Layout

The ring network adopts infrared communication, enabling the ring network to flexibly respond to sudden network anomalies. In case of an unexpected fault with a single cart or network cable at the site, the overall sorting operation status remains unaffected—this design minimizes risks to the greatest extent, ensuring uninterrupted sorting workflows.

Stable Operation

For the main ring drive, a high-efficiency and energy-saving linear synchronous motor is adopted; electric rollers are used for sorting. The narrow-belt sorting speed reaches 2.5 m/s, which not only achieves stable operation but also realizes efficient sorting—balancing energy conservation with high-performance sorting needs.

System Modularity

For small-scale sorting sites, narrow-belt sorting can be deployed, with multiple chute openings set on both sides. This modular design allows for maximum space utilization, making the system highly adaptable to limited-space scenarios without compromising sorting capacity.

| Paecel Size: | (Min)160mm*80mm*1mm (Max)465mm*400mm*300mm |

| Parcel Weight: | 0.03kg~15kg |

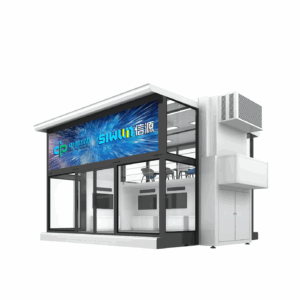

| Dual-Level Configuration; Electrically Operated Bilateral Slide-Out System; Equipped with LED Screen; Self-unloading from trailer to ground-ready operation |

Single-Level Configuration;

Electrically Operated Bilateral Slide-Out System;

Equipped with LED Screen

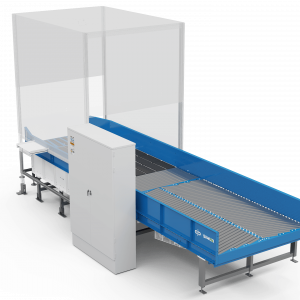

Automatic Parcel Singulator effectively separates parcels, enabling subsequent automatic sorting machines to work more efficiently in warehouse sortation tasks.

Static DWS Sorter plays a crucial role in optimizing product sortation processes in modern warehouses.

SIWUN Logistics' Advanced Sorting Solutions--Static DWS Sorter